IROC Rehab, Part 1

Late last year we planned to embark on a new project vehicle to build in our recently upgraded shop, the Sibley. Right out of the gate, the consensus was that it ought to be something attainable — something that could be driven hard and often without worry over rarity and potentially compromised value. We also craved something that could turn corners ably, and naturally, we wanted to stick with the familiar V-8/rear-drive architecture.

We considered a Fox-era Mustang but discovered that these too are rapidly escalating in value. Meanwhile, the obvious answer was right in front of us: a third-gen F-body. GM’s Camaro and Firebird have been gearhead favorites from day one, and while the ’80s iteration may have paled in the eyes of some enthusiasts when compared to earlier generations, we think the time is right to revisit these low-slung coupes, before they also become “too collectible” to provide budget-friendly fun.

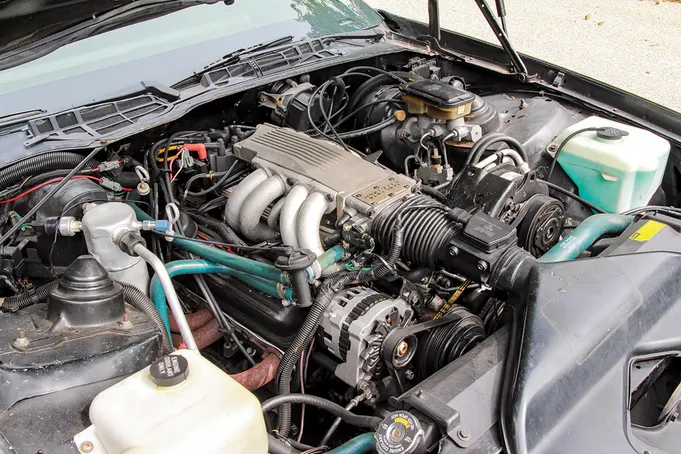

After selecting a third-gen F-body as the subject of our next project, we found a 1987 Camaro IROC-Z with the 5.7-liter Tuned Port Injection engine and then began gathering the parts needed to make it better. The actual work to get all of this stuff into the car would need to happen inside of two weeks

In a turn of events that still amazes us, we were able to locate a clean 35-year-old subject vehicle here in the Northeast relatively quickly, and one of the prime offerings of the period to boot: a 1987 IROC-Z with the 5.7-liter engine.

We were anxious to tinker with the Tuned Port Injection engine to find more power, but two things stood in our way. First, many of the aftermarket performance items for TPI third-gens are no longer made; second, our 350 soon developed a rod knock.

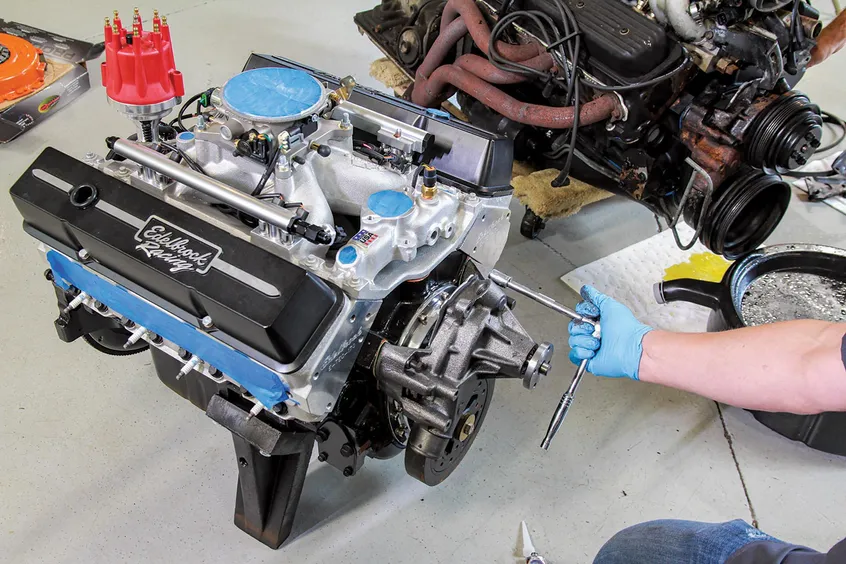

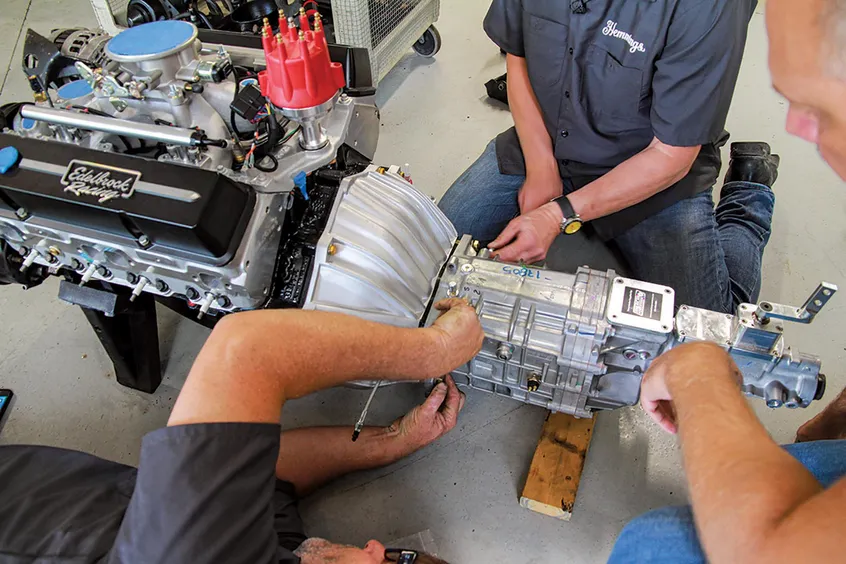

So, time for a Plan B, which led to a new 350 crate engine from Edelbrock. The package we received was based on a fresh 350 short-block topped with Edelbrock’s E-Tec aluminum cylinder heads, which are based on the GM Vortec design but with improved, larger ports and larger 2.02/1.60-inch valves. Feeding the new engine is Edelbrock’s Pro-Flo 4 electronic fuel injection system, which uses a four-barrel-style single-plane intake manifold but with injectors located at the end of each runner. The system is easy to program with the included handheld controller, and is also “self-learning,” so it will adjust the tune as the engine is driven. While our combination is rated for 380 hp, it can support up to 550.

After removing the driveshaft, exhaust system Y-pipe, radiator and associated hoses, and all of the engine wiring and ancillary bits, the crossmember was set on a dolly, the bolts were removed, and the car was raised on our new Bendpak lift up and away from the engine and transmission.

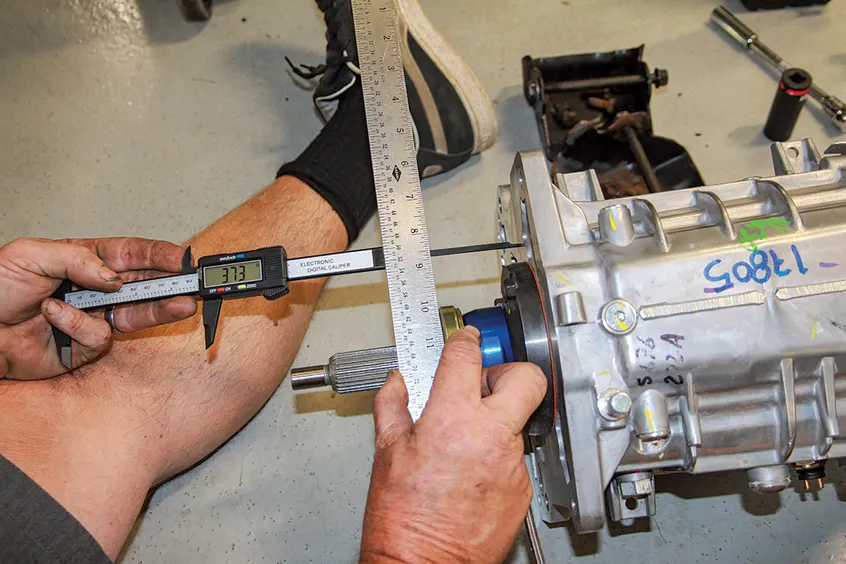

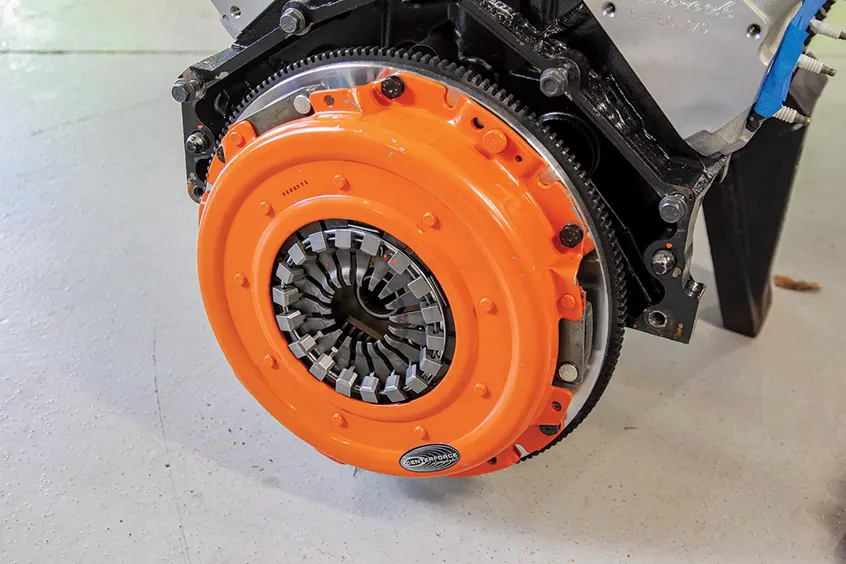

We could have backed this up with the Camaro’s 700-R4 four-speed automatic overdrive transmission, though having a third pedal would be better. To that end, we worked with American Powertrain to try one of their recently released five-speed conversion kits for the third-gen F-body. The centerpiece is a Tremec TKX five-speed gearbox, good for harnessing 600-plus horsepower but with a new, compact case design that lends itself to swaps. The package included a new clutch kit, plus American Powertrain’s Hydramax hydraulic clutch system, a crossmember, and a new driveshaft along with all other requisite installation parts and hardware.

The project is the first installment covering the Camaro’s progress, though we also intend to upgrade the suspension, restore some of the worn and broken bits inside and out, and get it back on the road in short order. This project is also the subject of a video series produced here at Hemmings, which you can watch right now on the Hemmings YouTube channel — all six episodes should be posted by the time you read this. Plus, we’ll have more details on the project here in HMM next month.

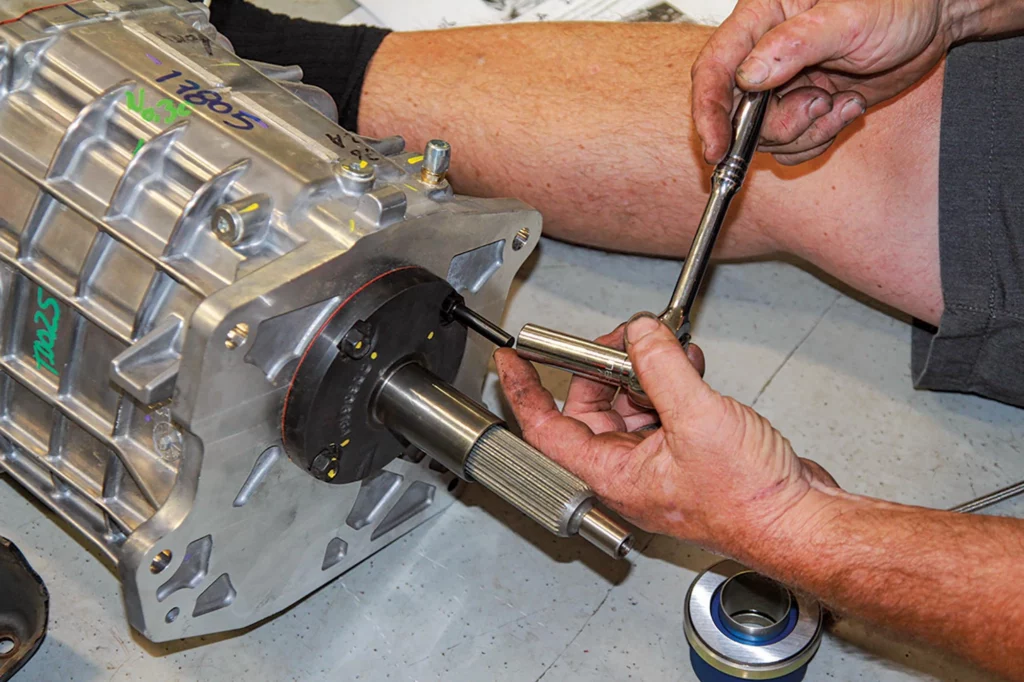

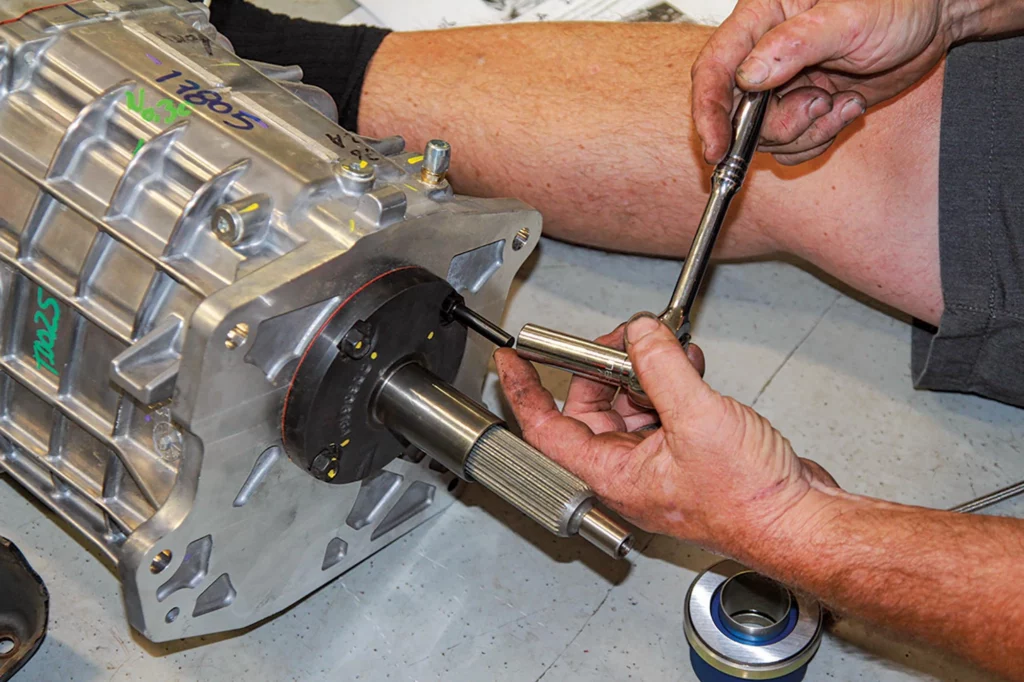

This pin must also be installed in the gearbox, replacing one of the stock bearing retainer bolts. The pin will locate the hydraulic throw-out bearing and prevent it from spinning when it contacts the pressure-plate fingers as the clutch is disengaged.

SOURCES

American Powertrain • 931-646-4836 • americanpowertrain.com

Bendpak • 800-253-2363 • bendpak.com

Blacktop Yacht Club • blacktopyc.com

Classic Industries • 800-854-1280 • classicindustries.com

Covercraft • 800-274-7006 • covercraft.com

Edelbrock • 888-799-1135 • edelbrock.com

Griot’s Garage • 800-345-5789 • griotsgarage.com

Summit Racing • 800-230-3030 • summitracing.com

U.S. Radiator • 323-826-0965 • usradiator.com