Do I need a fan shroud?

By Jefferson Bryant

The radiator in your car has one specific job- to exchange the heat from the engine coolant to the cooler air in the atmosphere. When you are driving above 40 mph, the air flow is high enough to do the job effectively on its own, but below 40 mph, where your vehicles spends most of its time when running, the air flow is not enough, and your engine begins to overheat. It is the engine fan that sustains the air flow through the radiator when driving under the 40-mph range. Maximizing that air flow is key to a properly functioning cooling system.

Mechanical Fans

Most OEMs use fan shrouds on the radiators to maximize the air flow. Prior to the mid-1970s, fan shrouds were often an upgrade, but this was also a time when automotive cooling systems were only dealing with cooling the engine, AC and automatic transmissions were less common. Before electric fans, these shrouds were quite large, as they had to extend from the radiator to the mechanical fan on the engine. Additionally, the fans were quite large as well, so the shrouds are quite large. Too often, the factory shrouds have been removed or broken. With a mechanical fan, there is no connection between the fan and the radiator on most cars, there is just too much distance between the two, so the fan simply can’t pull enough air flow through the radiator. Mechanical fans always need a shroud in order to maximize efficiency of the cooling system. Under low speeds and high demand (automatic transmission, AC, high temps outside), a mechanical fan without a shroud is a recipe for overheating.

The biggest problem with mechanical fans is that no matter what you do, they always steal horsepower. A mechanical cooling fan can rob as much as 40 horsepower from your engine, which is significant in any situation. There have been all kinds of band-aids over the years, the most common being the flex fan, which has flexible blades that flatten out at higher speeds, reducing the drag on the engine. The simple fact is that mechanical fans are outdated, and not used on many new vehicles built today. If you are going to keep your original mechanical fan for simplicity or originality, then you definitely need the matching fan shroud.

Mechanical fan shrouds are designed to stay tight to the fan blades. This is another place where hobbyists often go wrong. In an attempt to reduce the power draw from the fan, a smaller diameter fan is used. This actually compounds the problem, because you still have the parasitic loss from the fan, but it is also now much less efficient because it is too far away from the shroud. A properly designed mechanical fan shroud has a fan opening that is 2 inches larger than the fan itself, yielding about a 1-inch gap all the way around. The gap is necessary to allow for engine and frame movement that naturally occurs when driving a vehicle. You do not want any contact between the fan and the shroud. Too much gap between the shroud and fan results in less efficiency, and the fan is robbing horsepower for no gain.

The mechanical fan must also sit into the shroud the correct amount. This is typically “half-in, half-out”, where half the of the thickness of the fan is protruding from the shroud (to the outside, not inside the shroud. You should be able to see half of the fan blade from the side of the shroud. If the fan sits too far outside the shroud, the shroud isn’t being used at all. If the entire fan is inside the shroud, then the fan is just spinning the air inside the shroud and not drawing as much air through the radiator. The fan needs to pull air in and expel it out the back as efficiently as possible.

Electric Fans

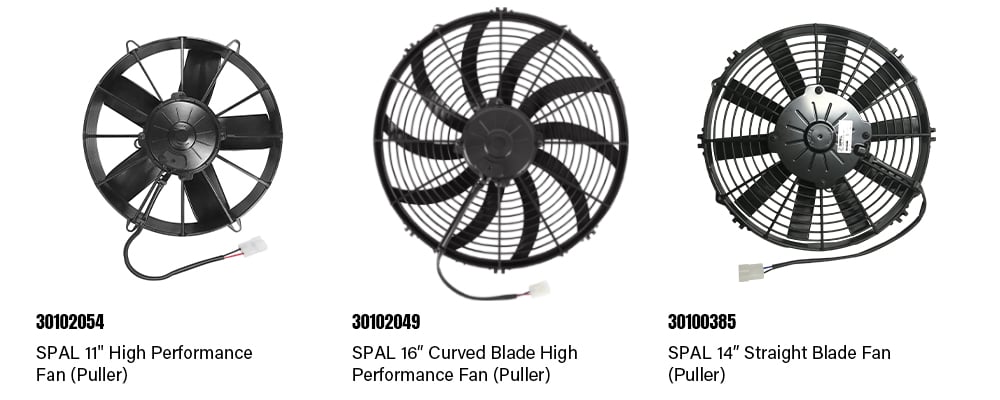

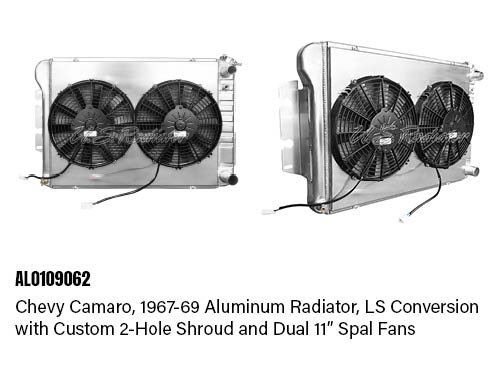

You can eliminate these inherent issues by switching to a more efficient electric fan, however this isn’t as simple as just slapping any old fan onto the radiator and calling it good. You need to match the fan to the application. Electric fans are thin, typically 2-3 inches thick from the mounting surface to the motor, US Radiator recommends allowing a minimum 4” of space between the radiator core and your pulleys or water pump to leave space for a quality HP electric fan. This is quite often the limit of how these fans are installed in custom builds, without a shroud. If your fan covers 70% or more of the radiator, then a shroud may not be necessary. This would be like a typical 1965 Mustang radiator with a single 16-inch fan, the radiator core is 21×16, 336 square inches of surface area. A 16-inch fan with 201 square inches of fan area yields about 60% of the radiator covered. If there is nothing stacked in front of the radiator, this is still slightly under the minimum 70% rule. You can’t stack two fans on a stock-size 65 Mustang radiator, it isn’t wide or tall enough, so you need a single 16 with a fan shroud for the best efficiency. There are multiple areas of concern for the electric fan- size, CFM, Style (pusher/puller), and radiator stack. We will get into the selection process in a future article, but here are the basics:

Size- Electric fans come in many sizes, but the most common for automotive applications are 12, 14, and 16” diameters. Most automotive radiators are too small for two 16” fans, especially without a shroud, so you usually get a single 16, maybe two 14s, or two 12s. For example, the core of a 68-72 GM A-body radiator measures 28 inches, so you can’t even get two 14s across the core without a shroud, leaving you to use a single 16, or a 16/12 combo. The A-body core measures 17×18, which is 476 square inches of surface area. A single 16” fan has a surface area of 201 square inches, leaving 276 square inches of un-used radiator core, this is less than 50% efficiency when the vehicle is not at speed. A shroud would eliminate that efficiency loss. You could run a 16 inch and a 12-inch fan without a shroud on the same radiator and you would have 66% coverage, which is still under the 70% golden rule.

Style- This refers to pusher or puller style of fan. Pullers are the most efficient and useful style of electric fan. All fans present some level of restriction to free flow, but a pusher fan puts all of that restriction in front of the radiator, reducing the core’s total potential air flow. When mounted as a puller, the dead air restriction is positioned behind the core, so the radiator gets full flow, it just might not have as much flow as possible in the restricted area. Most fans have a motor diameter of 3-4 inches, plus the frame, this is the restrictive area. Pullers are always better than pushers, but you can’t always use a puller.

CFM- All electric fans are rated in terms of CFM (Cubic Feet Per Meter). This is a free-air speed with zero restrictions, so as soon as you put a radiator stack in front of it, that CFM rating is reduced. The total airflow is the better metric for choosing a fan. The higher the static airflow, the better the fan can pull through the radiator. “The key to a good quality electric fan is the motor” Phillip Cochran of US Radiator told us, “A good quality fan will pull good CFMs under a load, CFM at zero static pressure is not a good barometer for an electric fan.”

Stack- This is the thickness of your total radiator stack. If you have a manual-transmission and no ac, then you likely just have a single radiator in front of the fan, whereas a pro-touring build likely has a radiator with transmission cooler, AC condenser, possibly an oil cooler, and maybe even an intercooler for a turbo or super charger in front of that fan. The larger the stack, the harder it is for the air to flow through all the cores.

Mounting- Many electric fans come with special mounting zip-ties that go through the radiator core. US Radiator does not recommend using these. You want to avoid damaging the fins and tubes, so a shroud is the best solution for any electric fan. If you can’t use a shroud, then brackets that secure the fan(s) to the radiator support or radiator mounts are suggested.

Electric fan shroud design is a little different than mechanical fans, some good and some not so good. The main thing is the depth. Unlike a mechanical fan, the electric fan can’t touch the engine accessory drive, so there is potential for a depth issue vehicle to vehicle. Luckily, the electric fan placement isn’t critical as along as it covers the core, so there are options. The other issue is depth to the core itself. Electric fans are designed to be very close to the radiator, but with a shroud, the fan needs to be a minimum of ½-inch from the core, but a little further back is better. 1-2 inches allows the fan a more efficient area to draw through the radiator. Anything less than ½-inch might as well be mounted directly to the core. A good shroud design creates a funnel in front of the fan to draw air through the radiator.

A properly designed fan shroud maximizes your cooling system’s efficiency, whereas a poorly designed shroud can be restrictive. When the vehicle is at speed, the air flow is reduced by the shroud, so a free-flowing fan system is critical for both low speed and high-speed travel. Building a fan shroud can be a daunting task for the average hobbyist without metal shaping equipment. The fabricators at US Radiator have the tools and knowledge to get this job done efficiently with good looks in mind. If your ride doesn’t have the most efficient cooling system, give them a call at (323) 826-0965 or check out their website at usradiator.com and see how they can help get you on the road to stable engine temps.