Keep Your Cool

Automatic transmissions generate a lot of heat, and heat is what kills an automatic. Automatic transmissions do not use coolant like an engine does; instead, the hot trans fluid is sent out of the case to a cooler in the front of the vehicle, and back into the transmission. This is where a lot of folks get into trouble with their automatic transmission swaps: the cooler should be in the radiator, not in front of it.

The main issue is that like engines, transmissions have a desired operating temperature where they operate the most efficiently. A modern automatic transmission is designed to operate between 165-230 degrees Fahrenheit, with the optimum temp range being 175-220 degrees. Under 165 degrees, the fluid is thicker than it should be. This is very hard on seals and valves because thicker fluid requires more effort to move. This is one of the reasons that transmission fluids are vehicle-specific: the flow rates, additives, and overall viscosity matters inside an automatic transmission.

When a transmission heats up beyond the safe zone, which for most transmissions is above 230 degrees Fahrenheit, the fluid gets too thin and starts to cook. Much like engine oil, trans fluid loses its viscosity, leaving the transmission internals primed for significant friction wear. At 240 degrees, the seals begin to harden, then the clutch plates begin to slip, burning up the friction material on the clutches. All that heat starts burning the fluid, which leaves behind carbon coking, the same stuff you get on exhaust valves, which is very sticky. Even with a fluid change, the damage is done. At 300 degrees, an automatic transmission is pretty much toast. It may not be dead, but it won’t live much longer without deep clean servicing.

Many gearheads think that the internal trans cooler in radiators is unnecessary and that simply strapping an external cooler to the front or back of a radiator is good enough. While that is the way you do it if you don’t have an internal cooler in the radiator, it isn’t the best way to do it. The issue with external coolers is that they can’t regulate the heat. It is simply an uncontrolled air-to-liquid cooler; if there is air passing through it, some level of cooling is happening. This means that your transmission takes much longer to get up to operating temperature, wearing out the seals and valves for a much longer time period. Once the transmission does get to operating temp, the heat may or may not be removed, as an external cooler can only exchange so much heat, and you get no cooling when sitting idle. If you do use an external cooler, it needs to be large enough to service the transmission you have and not be too big or too small.

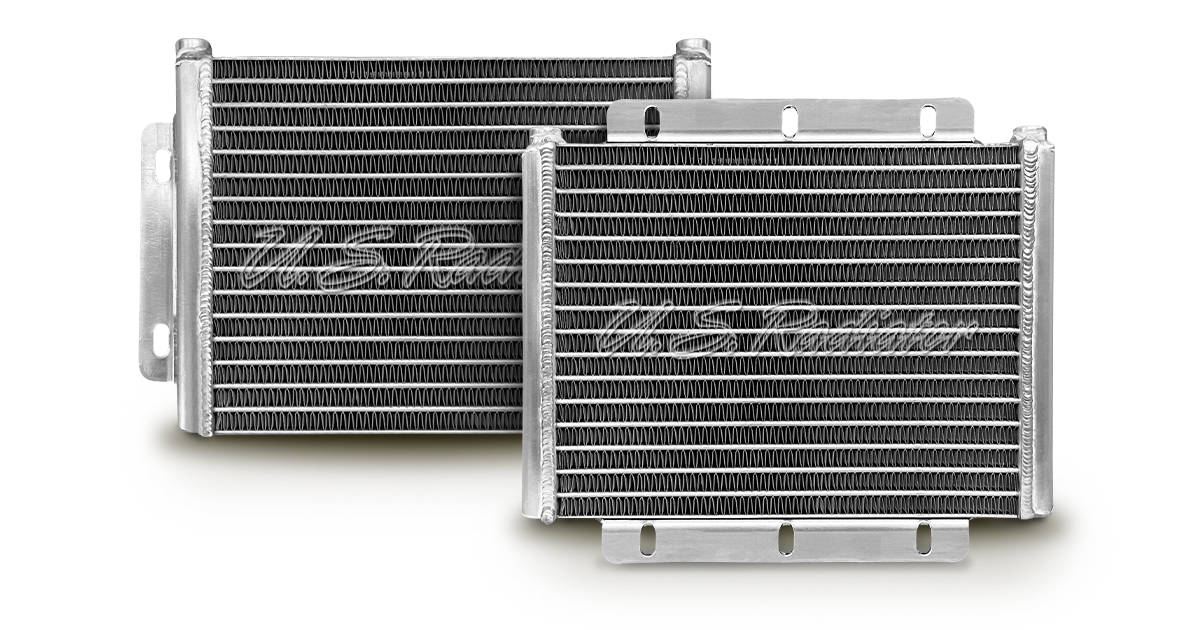

Photo: U.S. Radiator

The internal cooler, however, gives you several benefits. First, it helps bring the transmission fluid to operating temp much faster, because it uses engine coolant heat to warm the trans fluid. When the cooler is at operating temperature, it maintains that temp much better because the engine coolant buffers the overall temps inside the radiator. This keeps your transmission in the right operating temp. You might be thinking “But my engine runs at 215, but the trans temp gauge says 175, why isn’t it warmer?” That is because the internal cooler is almost always mounted on the outlet side of the radiator, so the trans cooler gets cooled by engine coolant that has already passed through the radiator. This is the best way to regulate transmission cooler temps.

There is a time and place for external coolers. They are not inherently bad, just often incorrectly used. If you have a vehicle that weighs a lot or carries heavy loads, such as towing, then there is an increased strain on the transmission that inevitably will push the temperatures up. If your existing in-tank cooler can’t cope, you can add an external cooler to boost the cooling factor. This should be done after the in-tank cooler, which allows the radiator to do the heavy lifting and uses the external cooler to provide additional support. Utilizing both coolers yields excellent results, with the in-tank cooler regulating the overall temp, but the external reducing the temps when it gets too hot. In most applications, however, the external is simply not needed.

Source: U.S. Radiator

All of this goes the same for oil coolers. You can easily run an external oil cooler, but even factory oil coolers often are routed through the radiator tank to equalize the temperatures. When oil gets cool, it gets thick. Your engine wants to run at a certain temp, the oil should be maintained in that same temp range. The internal cooler is the right way to do the job.

U.S. Radiator can build custom radiators for your project. If you want to add a trans cooler or an oil cooler or even both, they can do it. Give them a call at (800) 421-5975 to discuss your vehicle and get the right radiator today.